Creates 8 random gate outputs from one gate input signal which can be as high in frequency as an audio signal. Lots of creative possibilities with this module.

Welcome to stripboard heaven! Here you'll find all the projects I used to build my DIY Modular Synthesizer. I'm using the 'Kosmo' size standard but I also build Eurorack sized modules. All layouts are made by myself and verified to work. The schematics they are based on come from all over the internet. If you're on a PC or MAC, there's a complete MENU in the sidebar. For mobile devices the menu is in the black 'Move to...' bar below this text.

Tuesday, 13 April 2021

Synthesizer Build part-42: 8 RANDOM GATES by Yusynth.

Friday, 30 October 2020

Synthesizer Build part-35: RESONANT LOPASS GATE (Buchla 292).

An awesome sounding combination of a Voltage Controlled Amplifier and a LowPass Filter using Vactrols. It has three modes: VCA, VCF or Both. Prepare to fall in love with this one!!

The layout I made for this module worked rightaway but I did some experimenting with the Vactrols. I ordered a batch of VTL5C4 vactrols and they have now arrived but the Vactrols I made myself seem to work so well that I was at first hesitant to replace them. I have now tried them and they worked well but a bit too slow for my taste so I put my home made ones back in. I recommend you use VTL5C3's in this circuit or make your own like I did. However this is really a matter of taste. One of the videos I posted below uses VTL5C4's and it just sounds awesome so don't take my word as gospel please.

Here's a video demonstrating the sounds you can get from this module (listen with headphones to get the best effect). When I say "In 'Both-Mode' you don't get Resonance" what I mean is that you don't get self-oscillation in 'Both-Mode'. Resonance still works. When watching this video please keep in mind that I didn't yet know how to properly use this module. I'm simply turning knobs to see what happens, nothing more. Imagine what a skilled synth user could get out of this module when it already sounds so cool in the hands of a noob like me. ^____^

It would be very cool to have three or four of these Resonant Lopass Gates in a modular synthesizer set-up and to use them partly as VCA's with a twist. You can do some really cool things with this module, I know that. But I myself haven't figured out yet in how many ways you can use this.

Monday, 30 March 2020

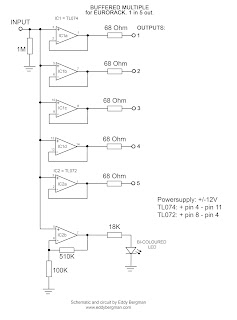

Synthesizer Build part-25: DUAL BUFFERED MULTIPLE with LEDs.

I have finished the case for the second stage of my DIY synthesizer so now I can continue building modules and writing about them here. So the first thing I wanted in the new case was a Buffered Multiple. I have built a number of filters that need a 1V/Octave signal but I only had one output to provide it so I designed this little circuit. You can connect anything you want to the inputs: Audio signals, LFO signals, 1V/Oct. CV, Gate signals, you name it. Any voltage presented at the input is replicated at each of the four outputs and if you need more you can connect one of the outputs of the first stage to input 2 and so get a total of 7 outputs for one input.

This module will work on both +/-15V and +/-12V. Running it on 15V just means it can handle a bit higher voltages but as the average synth only uses control voltages with a maximum of +/-10V it really won't matter.

Here is the schematic drawing showing one stage. As you can see it's just 4 non-inverting buffers with all the inputs connected together. The module is just two of these on one piece of stripboard. I've put 100 Ohm resistors on the outputs for some extra protection. Because there's (practically) no current flowing these resistors won't influence the output voltage. I've tried 1K resistors but they influence the voltage and bring the notes down by a few Cents. I did a lot of testing on this and 100 Ω is really the maximum. Of course you can use 1K and retune your VCO's but I want to keep it as clean as possible. If you don't feel comfortable with resistors on the outputs you can leave them out all together. In my own version I left them out too and replaced them with wirebridges. The IC's have built-in short-circuit protection anyway.

Stripboard only. The 100 Ω resistors can be replaced with wirebridges. In fact I would use wirebridges instead of resistors to begin with. I chose 100 Ω because that's the highest value that still doesn't cause a drop in voltage but you can easily do without them and use wirebridges instead. The resistors are there to offer some protection to the chip should you connect a live signal to one of the outputs by mistake, but most chips have internal protection from that anyway:

Of course you could also use two normal LEDs; one for the positive cycle and one for the negative cycle. It's up to you.

Here's the schematic for the LED version. I've connected it to output 4 of each of the two sides but you can choose any output that's convenient. Because the LED is buffered it takes no voltage away from the output. This schematic drawing shows only one side because the second side is identical to this one.

Here are a few pictures of the finished product. I made a little L-Bracket (also visible on the layout) so I could mount the board at 90° to the panel.

This is the version with the LED's installed. The right LED is displaying the voltage of the Gate signal which is +5V. The left LED is displaying the 1V/Oct signal which is a bit lower and thus the LED shines a bit dimmer.

The print up close. As you can see mine has more wire bridges because I forgot that some connections can be made directly under the IC. So I did it the hard way. The first picture below is the original module without LEDs. The second one is after I converted it and added the LEDs.

Because I added the LEDs later I had to use some jumpwires on the stripboard to connect it all together.

EURORACK VERSION.

I left in 6 empty strips at the bottom so you can hot-glue the stripboard to the back of a Eurorack panel and use the side of the sockets for extra support, so the components will stick out above the sockets (or below the sockets, which ever way you look at it ^___^). If you have an other way of mounting it and don't need the extra empty space then just saw it off.

Monday, 9 December 2019

Synthesizer Build part-8: 8 STEP SEQUENCER.

EDIT: There is now a new and improved version of this sequencer available on this website. I redid the design and included some extra features like external clock input and a CV Offset control. This makes the sequencer much better to use and it is no more complicated to build than this original design. So please go over to project 49: 8 step sequencer version 2 if you want to build this 8 step sequencer.

Here's the schematic drawing for this sequencer. The connections of the rotary switch are not correct in the schematic. They must be offset by one step from those of the potmeters. So step 1 is reset by the pulse from step 2 so pin one of the switch goes to output 2 of the CD4017, pin 2 of the switch goes to output 3 of the CD4017 etc, etc.

In the schematic above the on/off switch is placed after the voltage regulator to easily switch the sequencer on or off without causing switching pulses on the voltage rails. The complete on/off switching is done with the switch of the powersupply which controls the power of your whole modular synthesizer.

Be careful when you wire this up, note that the jumper (or wire bridge) for output 5 is connected to pin 10 of the chip so the left bunch of jumpers skips a copper trace at output 5. Look carefully at the layout! If you want to include switches to mute individual channels then put them in series with the diode!

NOTE: All potmeters in the layout are shown from the front side!

A better solution, and one you should consider if you are comfortable with designing simple circuits with opamps, is to add a DC-Offset feature to this sequencer. That way you can get the lowest notes down to 0 volt without influencing the dynamic range of the sequencer. It's easy enough to do. This is not included in the layout or schematic though.

Here's a close-up of the stripboard:

Bill of materials for the layout version. You'll need ten (10) 100K potmeters instead of the 8 mentioned in the B.O.M. below. You need one for speed control and one for offset (if you build version 2 of this sequencer which I strongly advise you to do. Go to project 49) :

The sequencer is build up around the CD4017 decade counter chip, using a CD40106 to create the clock pulses which also serve as the 'Gate' pulses.

The CD40106 hex inverter is used as a low frequency oscillator giving off squarewave pulses who's frequency can be controlled by the 100K potmeter. I used a 15µF electrolythic Capacitor although a 10µF will do just as well. But a little higher value will give you slower speeds so you could even try a 22µF cap. The clock pulses can be interrupted by switch S-2 to give you a chance to tune that particular channel. Sometimes it can happen that after using the 'Stop/Run' switch that the sequencer jumps to channel one. If that happens try using a different CD40106 chip. You might have a fake one and they can be quircky in their behaviour.

All the collectors of the transistors are connected straight to the 8 Volt power rail and the emitters are all connected to ground.

It's better to just follow the stripboard layout and skip the whole transistor setup and connect the output of the CD4017 straight to the potmeters. I'm using transistors as a sort of buffer and to make this sequencer future proof for other experiments so I can draw some current from the outputs should that be necessary. But you can just leave them out it you want to. Makes it so much easier.

By setting the different potmeters, you can create the different tonal paterns the sequencer produces.

Because the potmeters are simply used as voltage deviders, it doesn't really matter which value they are as long as it's 50K or over so that they don't draw too much current and as long as you use the same value on all 8 channels.

You can tap the 'Gate' pulses straight from pin 3 of the Speed Control potmeter to the Gate output jack mounted in the panel. The pulses are really clean looking 8 Volt squarewave pulses with a 50% duty cycle so if you use the gate output into the ADSR, it will sound as if a key is pressed every time the sequencer switches to an other note.

A ten step switch is used to select the length of the sequence. It can be anything from 1 to 8. Btw, you can easily make this a ten step sequencer by connecting the last two pins from the CD4017. I made it an 8 step because I didn't have enough space to mount everything horizontally and because 8 steps is more natural for music than 10 steps because you normally have 4 notes in a beat. So multiples of 4 are better. The potmeters on my panel are mounted vertically and I could only fit eight of them below eachother anyway.

Connect the wiper part of the switch to pin 15 of the CD4017 and the wires from 1 to 8 to their relative position on the switch. Connect pins 9 and 10 of the switch together and connect the ninth output from the CD4017 to that. The pulse going into pin 15 of the 4017 will reset the chip and the counter will start over again.

Don't forget to connect pin 13 of the CD4017 to ground.

It is best with this build to make the panel first and connect all the components and do the essential wiring while you have access. Then make the circuitboard and connect the wires to the panel. Solder the resistors straight to the LED's and the diodes to the wipers of the potmeters. Connect the cathodes together and solder a wire from there to the CV output jack.

I used 5mm LED's and I made the holes in the panel by using a drill rather than a hole enlarger bit which I normally use to enlarge the pilot holes I drilled. The drill is usually a little bit less then 5mm and therefor the LED's will sit very tight and don't even need to be glued in place (although it is best to hot-glue them in place anyway).

Do not forget to solder a big 470µF capacitor on the input of the 7808 voltage regulator. Otherwise pulses will bleed through onto the power supply rails and you'll hear the tone sequence even if the sequencer isn't connected to the CV input of the VCO. I also included an ON/OFF switch (S-1) on the panel just to have the option to shut it down. It's the only panel in my synth build to have an ON/OFF switch.

TUNING THE SEQUENCER:

To tune the sequencer, simply set it to the lowest speed and use switch S-2 to interrupt the clock pulses and stop at each channel. Then you can tune that particular channel using a tuner or simply by ear, by turning the potmeter and then you turn switch S-2 back on. The sequencer flips to the next channel, you turn it off again with S-2 and tune that note, then you flip the switch again and jump to the next channel, etc, etc. It's very simple and very effective. :)

That's all there is to say about this. It's one of the most fun panels for the synthesizer but one of the most tedious to build. It cost me 6 hours straight to design and build it but luckily it worked straight away.

Here's a little demo of the sequencer. This was filmed before I put in switch S-2 so I had no option to tune the sequencer at the time of filming. I might make a new video soon:

Okay, that's another one done. I hope you enjoyed it. If you have any questions about this build then please leave them in the comment section below or in the Facebook Group.

.jpg)